For capillary tubing, the selection of tubing fluid should consider the ambient temperature (to prevent freezing). In vapour or cryogenic services, the dry leg should have a self‐purge.Ī particular attention should be paid to the protection and heat tracing of dry/wet legs. Differential pressure transmitter used without diaphragm seals and capillaries should have block and bleed valve manifolds as a minimum. The use of wet legs with intermediate liquids and zero adjustment implies more complex range calculation and higher maintenance needs. Capillaries should be protected from damage using a basic channel system, allowing sufficient bend radius for the capillaries.ĭiaphragm material should be carefully selected according to the type of fluid (e.g. This should be provided with a flushing ring mounted between the process flange and the diaphragm seal.Ĭapillaries should be specified at the correct length, without the need for coiling excess capillary that is surplus to the run. Selectionĭifferential pressure measurement could be considered for most applications with liquid–gas or liquid–liquid interface level measurement.ĭifferential pressure transmitters can be used in severely turbulent, dirty, in presence of foam above the liquid or fouling service with diaphragm seals and capillaries.ĭifferential pressure transmitter with diaphragm seals and capillaries are preferred.

Sufficient support should be provided for minimizing the weight transferred to the nozzles.

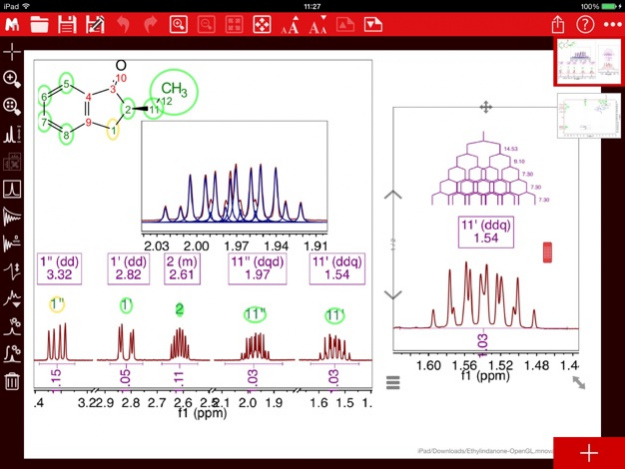

#Mestrenova new interface calibrate verification#

DBB/SBB valves, flushing ring, etc.) to the nozzles should be verified with the nozzle local stress verification (static and dynamic/fatigue). The mounting of heavy instrument (including all accessories, i.e.

The transmitter should be installed below the bottom nozzle.įor heavy crude oil dirty, foaming, fouling or clogging services the DP with remote diaphragm seal is recommended with nozzle, flushing ring and heat tracing (e.g.

To compensate a density measurement should be provided.įor vessel under vacuum, DP with remote diaphragm seal is recommended. This occurs typically for an interface measurement between oil and water the case of presence of “heavy” oil (the oil density value is nearly the same as the water density value).Īccuracy depends on the liquid density variation. This depends on the DP range, accuracy and distance between the upper and lower nozzles. If both density values ρ2 and ρ1 are similar, the interface level measurement may nearly not be detected by the transmitter. The combination of density difference and the distance between the upper/lower nozzles should result in a minimum DP range of around 30 mbar. For an interface measurement between two liquids the limitation is derived from Equation. Using the same principle and Equation, density of a single fluid can be measure if both tapping are permanently and fully immersed.įollowing the principle, measurement of several interface layers can be considered by staging each interface level measurement. For an interface level measurement it should be h interface. Interface measurement requires its own connection into the upper and the lower phase.Įquation is applicable if there is only one variable. H interface : Interface Level between the Liquid 1 and Liquid (m)

0 kommentar(er)

0 kommentar(er)